Performance characteristics

DWX type single hydraulic pillar for mining is a key scientific and technological achievement promoted during the National “Tenth Five-Year Plan” period. The product has more than ten national invention and utility model patents, and won the second prize of National Technological Invention in 2011.This product is a new-generation coal mine support product developed and directly promoted by China University of Mining and Technology. It adopts the principle of plunger suspension. Compared with the DW(DZ) pillar, it has the advantages of high safety factor, strong anti-bias load capacity, large stroke, light weight, easy inspection and maintenance, green environmental protection, and high cost performance.

Technical features

The principle of plunger suspension technology is adopted. The suspension force reaches four-fifths of the working resistance, and the column force is only one-fifth, which greatly improves the stability of the pillar, improves the carrying capacity and anti-bias load capacity of the pillar.

There are no welds on the movable column. Avoid accidents caused by broken welds, improve the strength and reliability of the column, and ensure the safety of miners.

The work schedule is large. It is especially suitable for working surfaces with large sinking of the top plate, soft bottom plate or large changes in coal thickness.

Pillars have a wide range of uses. Each specification can replace 2-4 specifications of the DZ pillar series. Reduce spare pillar specifications and reduce production costs.

The pillar is light in weight. The weight of the whole column is lighter than that of the piston pillar. The minimum height of the pillar is shortened, making it easy to move, transport and use.

There is no internal leakage in the pillar. Once it leaks, it is clearly visible, and it can be rehydrated or replaced at any time to avoid accidents that may injure people due to the leakage of the false top of the pillar.

The three-purpose valve is provided on the handle body. When the column is raised, the three-purpose valve does not rise with the movable column, which is easy to operate, safe and reliable.

The technical principles of sealing compensation and sealing expansion are adopted. It can effectively compensate when the seal is damaged.

Special environmentally friendly surface treatment technology is adopted. It has the properties of anti-corrosion, wear-resistant, and anti-collapse resistance.

Unique features of DWX pillar

Using a new type of electrophoretic coating process, the anticorrosive performance is greatly improved, and the normal use can reach a life span of 3 years.

The height of the high-post handle body adopts a humanized design. According to customer requirements, it can be designed between 1.2-1.5m, which is easy to operate, safe and reliable.

The rated resistance is 20% higher than that of conventional suspended single pillars.

Structure and working principle

The working principle of DWX type (plunger suspension type) hydraulic strut includes four processes: lifting column, initial support, carrying and returning column. They are summarized as follows:

1. The process of lifting the column and initial support

When lifting the column, insert the liquid injection gun in the pipeline system into the three-purpose valve oil injection valve body, hang up the locking sleeve, and operate the liquid injection gun. The high-pressure liquid from the pumping station passes through the liquid injection gun to open the spherical one-way valve in the three-purpose valve and enter the pillar, forcing the movable column to rise.

2. Carrying and overflow process

After the pillar is supported, it is in a load-bearing state. With the extension of the support time, the load of the top plate of the working surface acting on the pillar increases. When the load on the pillar exceeds the rated working resistance, the force of the high-pressure liquid in the inner cavity of the pillar acting on the safety valve pad exceeds the compression force given to the hexagonal guide sleeve by the pre-adjusted safety valve spring. When the safety valve spring, the safety valve pad and the hexagonal guide sleeve move together, the safety valve pad leaves the valve seat, the safety valve is opened, the liquid in the inner cavity overflows, and the living column shrinks. Rebalance the pillar pressure.

3. The process of returning to the column

When the pillar is recovered, insert the unloading handle into the unloading hole of the right valve cylinder of the three-purpose valve, rotate the unloading handle, force the valve sleeve, connecting screw, oiling valve body, etc. to move axially, compress the unloading valve spring, the unloading valve pad leaves the sealing surface of the left valve cylinder, the unloading valve is opened, the working fluid in the inner cavity of the pillar is ejected through the valve cylinder, and the living column retracts under the action of its own weight and return spring. Complete pillar recycling.

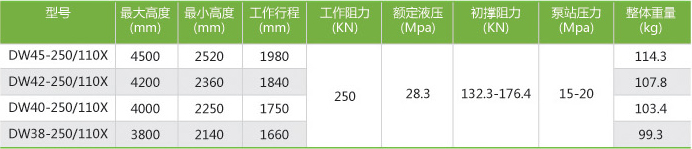

110 bore DWX (suspension type) single hydraulic strut

Technical features

This series of products implements the MT112.1-2006 "Mining Single Hydraulic Pillar" standard;

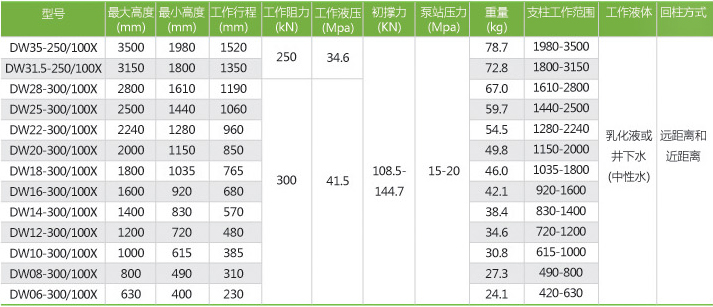

Model meaning: for example, DW35-300/100X;

D-represents the single hydraulic pillar; W-represents the external injection type; 35-is the maximum height of the pillar; 300-is the rated working resistance of the pillar; 110-is the diameter of the cylinder of the pillar; X-is the technical principle of suspension type